The purpose of this evacuation procedure is to establish a standard practice for correct evacuation of refrigerant from air conditioning units after exposing it to the atmosphere.

This hvac maintenance procedure will also serve as a guideline for newly hired employees in the maintenance or FM department, whoever will deal Air conditioning unit maintenance activity.

Scope of this standard maintenance procedure covers all equipment’s that need vacuum pumps to remove the unwanted gases and contaminants inside the system, i.e. Chiller Units, Package Units, Split A/C Units, Cold Store Units, Window Type A/C’s, etc.

It is the responsibility of the A/C engineer and technician to conduct evacuation process on every air-conditioning system after exposing it to the atmosphere. He should be competent enough and has a complete background in maintenance of air conditioning system to avoid running the system with improper evacuation procedure.

Maintenance supervisor and the site engineer should assure that this maintenance procedure will be followed during all maintenance activities related to evacuation of ac system.

Brief Description of Refrigeration Vacuum Pump

Refrigeration systems are designed to operate with only refrigerant and oil circulating inside them. When ac systems are assembled or serviced, air enters the air conditioning system.

Air contains oxygen, nitrogen, hydrogen and water vapor, these gases are considered as non-condensable gases.

These gases must be removed from the system in order to maintain and achieve normal life expectancy.

Non condensable gases are removed by vacuum pumps after the system is leak checked and found OK.

There are two kinds of moisture in the system, vapor and liquid. When it is in liquid state, it is much more difficult to remove.

Evacuation Procedure for Refrigerant System

Prior to the work, wear safety shoes, gloves, goggles and any other PPE as per the project and building requirements.

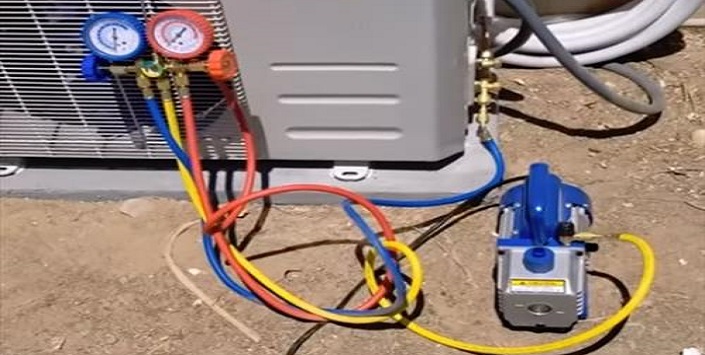

Prepare vacuum pump, gauge manifold, spanners and screw drivers.

After the system has been serviced and leak tested, evacuation process should be done.

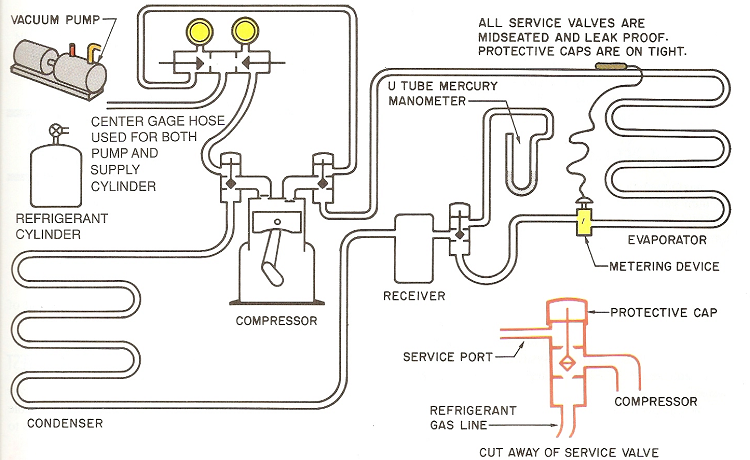

Thoroughly study the figure below for the system set up.

Connect the middle hose of the gauge manifold to the refrigeration vacuum pump.

Now connect the Low Pressure hose of the gauge manifold to the access charging valve suction line of the refrigerant compressor.

Connect the High Pressure hose of the gauge manifold to the access charging valve discharge line of the refrigerant compressor.

Make sure that all connections are tight.

Mid seat all service valves and assure all leak proof protective caps are tight.

Switch ON the vacuum pump. Make sure the pump is plugged to its correct voltage rating.

Check the operation of the vacuum pump. Exhaust moist air must be coming out of the vacuum pump.

When the vacuum pressure reaches the desired level (28 inHg), close the valve of the vacuum pump and allow the system to stand for some period of time to see if pressure rises.

In case the pressure rises and stops at some point, a material such as water is boiling into the system. If this is the case continue evacuating.

Again if still the pressure continues to rise, there is a leak and the atmosphere is seeping into the system. In this case the system should be pressurized and leak check again.

Usually, vacuum time process depends on the size of the equipment; the higher the capacity of the equipment, the longer vacuum process is needed to reach the desired vacuum pressure.

References

Refrigeration and Air-conditioning Technology, 3rd Edition By: William C Whitman & William M. Johnson