Purpose of this method is to establish a standard maintenance procedure for refrigerant gas checking and charging on Air-conditioning units.

The method will also serve as a guideline for newly hired employees in the company which will be dealing with air conditioning unit maintenance works.

Scope of this standard covers all equipment’s which use refrigerant gas as their cooling agent i.e. including but not limited to Chiller Units, Package Units, Split A/C Units, Cold Store Units, Window AC and fan coil unit maintenance etc.

It is the responsibility of the A/C Technician to check and charge refrigerant gas into the equipment.

Technician shall be competent enough and has a complete background in Air-conditioning system to avoid release of gas into the atmosphere.

The refrigerant gas chemical is considered part of Ozone Depleting Substances ODS, therefore care should be observed when handling these substances.

Maintenance supervisor and the engineer should assure that this maintenance procedure will be followed including the applicable local regulations.

Refrigerant Gas Checking Procedure

Prior to the start of refrigerant charging work, wear necessary PPE i.e. safety shoes, goggles and safety gloves.

Prepare gauge manifold, spanner, adjustable wrench and R-22 or any approved refrigerant gas cylinder.

Open the cover of the access charging valve for both suction and discharge line of the A/C equipment using adjustable wrench.

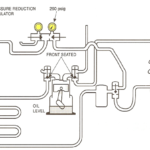

Connect the LP (Low Pressure) hose of the gauge manifold to the suction side of the refrigerant compressor.

Now connect the HP (High Pressure) hose of the gauge manifold to the suction side of the refrigerant compressor.

If valves are connected after the access charging valve, open the cover of the valve using adjustable wrench and open the valve seat by using spanner.

Open the valve of the gauge manifold to obtain the suction and discharge pressure of the system.

Suction pressure should be 60 to 69 psi while Discharge pressure should be 250 to 275 psi.

For other refrigerant types, please refer to the name plate of the equipment or the compressor for the correct refrigerant charge pressure. Compressor should be running when getting the system refrigerant charge.

Close the valves of the gauge manifold. Close the valve seat of the access charging pin valve if available.

Remove the LP and HP hose of the gauge manifold to the access charging valve of the system.

Refrigerant Gas Charging Procedure

Prior to the start of refrigerant charging work, wear necessary PPE i.e. safety shoes, goggles and safety gloves.

Prepare gauge manifold, spanner, adjustable wrench and R-22 gas cylinder.

Connect the middle hose of the gauge manifold to the refrigerant tank.

Slowly open the valve of the refrigerant tank.

Again, slightly open the threaded connection of the middle hose to purge trapped air then tighten it again.

Open the cover of the access charging valve for both suction and discharge line of the A/C equipment using adjustable wrench.

Connect the LP (Low Pressure) hose of the gauge manifold to the suction side of the refrigerant compressor.

Now connect the HP (High Pressure) hose of the gauge manifold to the suction side of the refrigerant compressor.

If valves are connected after the access charging valve, open the cover of the valve by using adjustable wrench and open the valve seat by using spanner.

Slightly open the valve on the low pressure side of the gauge manifold to charge refrigerant on the suction side of the compressor.

Close the LP valve of the gauge manifold from time to time to check the actual pressure build-up in the compressor. Pressure should be within 60 to 69 psi. Check also the discharge pressure reading. Pressure should be within 250 to 275 psi.

Once the required suction and discharge pressure were obtained, charging can be stopped by shutting the LP valve of the gauge manifold.

Close cylinder or tank valve.

Disconnect cylinder from the gauge manifold.

Close all access charging valves.

Disconnect the gauge manifold to the compressor line.

External References

Refrigeration and Air-conditioning Technology, 3rd Edition By: William C Whitman & William M. Johnson