Purpose of this maintenance procedure is to establish a standard procedure for the proper flushing of air conditioning and refrigeration system with the use of dry nitrogen.

This standard method will also serve as a guideline for maintenance department employees during maintenance activity.

Scope of this standard covers all A/C and refrigeration equipments which require flushing of the system after exposing it to the atmosphere or during replacement of the refrigerant compressor.

Roles and Responsibilities

It is the responsibility of the air conditioning engineer and AC technician to conduct flushing of the system using dry nitrogen to assure that all soot, contaminants and sludge are removed from the system.

Maintenance engineer should be competent enough to use this equipment to avoid any damage and to provide the proper result.

The maintenance supervisor and the engineer should assure that this maintenance procedure will be followed strictly.

Abbreviations

A/C: Air-conditioning Units

PPE: Personal Protective Equipment

Nitrogen Flushing Procedure

You will always need to follow this procedure whenever replacing old compressor or when system is opened to the atmosphere.

Prior to start the work, wear safety shoes, gloves and goggles.

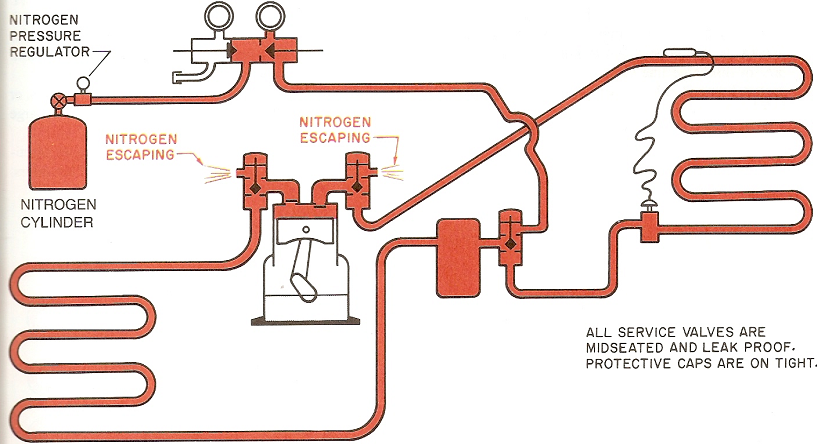

Prepare nitrogen tank with pressure regulator, adjustable wrench, gauge manifold, spanner, tube cutter or hacksaw.

Isolate the compressor by front seating the suction and discharge valve. If compressor is for replacement, flushing should be done first before installing the new unit.

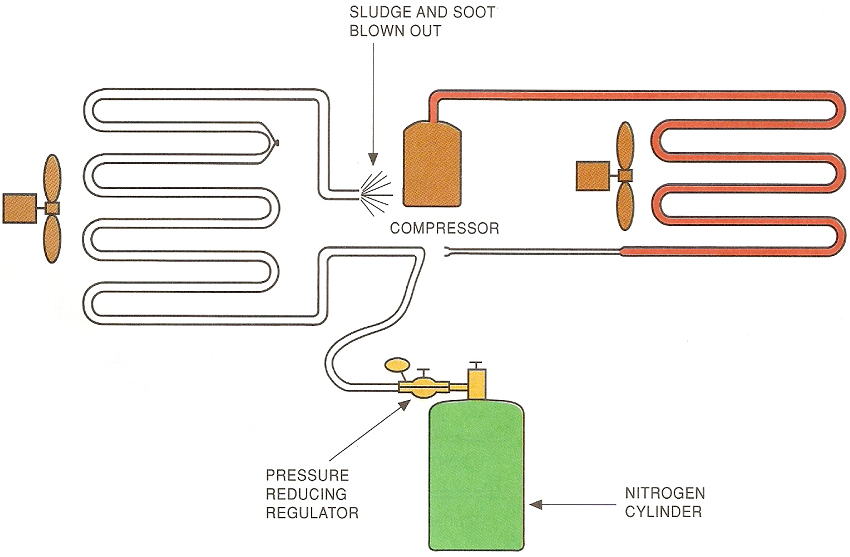

Use dry nitrogen to push some of the contaminants out of the system by simply attaching the nitrogen regulator to one of the lines and allowing it to blow out the other.

Do not exceed the system working pressure with nitrogen.

While compressor is isolated from the system, you can safely use 250 psig for high pressure refrigerant system flushing.

Disconnect the pipeline before the expansion valve device where a liquid line filter can be installed later.

Purge the Nitrogen through the liquid line toward the compressor and discharged out the compressor discharge line before the compressor is connected.

Disconnect the nitrogen after pushing off all contaminants at this point.

Connect the nitrogen to the expansion device side of the liquid line. This line may be purged toward the compressor suction line.

References

- Refrigeration and Air-conditioning Technology, 3rd Edition By: William C Whitman & William M. Johnson

- TESDA Refrigeration and Air-conditioning Manual