The purpose of this section is to provide guidance in preventive maintenance and basic fault tracing and provide instructions for corrective actions to remedy any faults. Go through this section, Fault tracing before contacting suppliers.

To ensure the air curtain operates at full efficiency the inlet/outlet grilles, fan impellers, housings and motors must be kept free of dust and debris. Build up of dust on the fan impellers can cause vibration, noise and excessive wear on the motor bearings.

Frequency of cleaning will depend on the environment, but we would recommend that the unit be cleaned a minimum of every 3 months (failure to adequately maintain the unit and provide a suitable cleaning schedule will result in performance degradation and reduce the life expectancy of the air-curtain).

Remove the grille core from the air curtain. Vacuum and clean the build-up of dirt and debris within the air-curtain (please note that the motor(s) are permanently lubricated and require no additional lubrication). If filters are fitted, ensure these are regularly inspected and cleaned or replaced. All dirty or blocked filters should be immediately

replaced.

Once the air curtain has been cleaned check all electrical connections within the unit ensuring terminals are tight and that crimped connections have not become loose.

Refit the grille core in the recessed grille. Reconnect the electrical supply and fully function test the air-curtain to ensure correct operation (See Commissioning).

The below list of activities provides help in identifying types of faults that are easy to remedy without the assistance of specially trained personnel.

Overheat safety cut-out

An overheat fault in electric heated units may cause the overheat safety cut-out(s) to operate.

This is indicated by flashing LEDs on the remote control and a red status LED on the PCB inside the air curtain.

Overheat safety cut-out indication

For electric heated air curtains the PCB includes a fault indication signal for if the overheat safety cut-out on the electric heater operates.

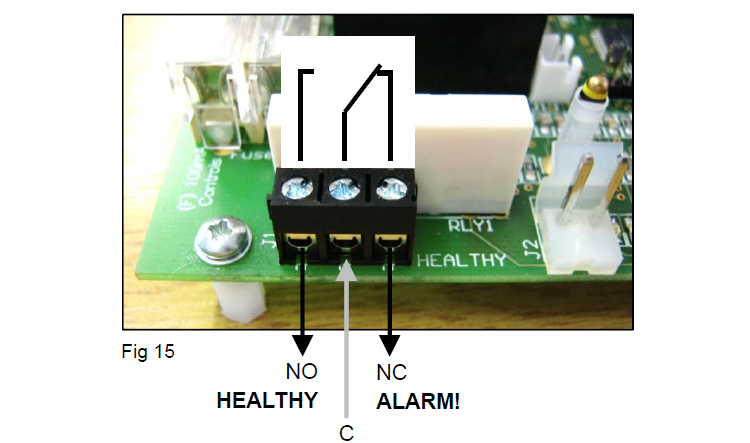

Volt free changeover contacts (6A 250VAC 30VDC) can be wired via the 3-way screw terminal “HEALTHY”.

Refer to section below for Overheat safety cut-out, for how to reset a overheat safety cut-out situation.

Before resetting ensure there is adequate air flow from the air curtain and the unit has been commissioned as per the standard procedure.

To reset a overheat safety cut-out trip:

Step 1 Switch off the electrical supply to the air curtain.

Step 2 Allow time for the air curtain to cool down; typically 10 minutes.

Step 3 Switch on the electrical supply to the air curtain.

Step 4 Press the Auto button on the Ecopower remote control 4 times. Air curtain heaters will then operate and after 30 seconds the LEDs on the remote control will stop flashing and the status LED on the Ecopower PCB in the air curtain will flash green.

Fuses Faults

In the event of an electrical fault internal electrical fuses may operate.

There are two internal fuses located on the Ecopower PCB inside the air curtain:

Fuse 6.3A (T) supplies the fan motors within the air curtain ▪ Fuse 100mA (F) controls the operation of the motherboard

Ecopower PCB status indication

There is a status LED on the Ecopower PCB inside the air curtain (See LED shown on Wiring Diagrams)

This indicates the status of the Ecopower Control system as follows:

LED flashing green — operation normal

2. LED flashing red — low supply voltage, remote control not plugged in or RJ cable fault

3. LED permanently red — overheat safety cut-out(s) open circuit from an overheat situation

Air Curtain Preventive Maintenance Method

Always disconnect the plug from the power supply before any maintenance or repair work is carried out.

WARNING: Failure to adequately maintain the unit and provide a suitable cleaning schedule will result in a loss of performance and reduced life expectancy of the air-curtain and possible overheating and fire risk with electric heated units.

Every week

NOTE: Weekly maintenance can be carried out by the Cleaner or Janitor from floor level.

Turn off the air curtain to prevent dust entry, then clean the face of the recessed grille using a vacuum cleaner with an extension tube and brush.

Every 3 months

WARNING. Before servicing, isolate and disconnect the air curtain from the electrical power.

WARNING: The following servicing and maintenance must be carried out by a competent electrician or a Thermoscreens appointed technician.

Clean and inspect the inside of the air curtain as follows:

Step 1 Open the hinged inlet grille using a flat bladed screwdriver to release the quarter turn fasteners.

Step 2 Clean and remove any build-up of dust and dirt within the air-curtain (inlet/outlet grilles, fan impellers. housings and motors) using a vacuum cleaner and soft brush.

NOTE: Build-up of dirt on fan impellers can cause vibration, noise and excessive wear on the motor bearings.

Step 3 Check within the unit to ensure all electrical connections and crimped terminals are tight and that all cables are in good condition.

Step 4 On electric healed air curtains, remove the fan deck(s) as follows to inspect electric heaters, electrical wiring and connections and to remove dust, dirt and debris:

Unclip the fan motor electrical connector.

Unfasten 4 x M6 nuts/bolts on each fan deck.

Unfasten M4 screws at bottom edge of fan deck.

Carefully lift the fan deck away from the air curtain.

Close and secure hinged inlet grille after servicing. Reconnect electrical supply and test to ensure correct operation.