Applying the six sigma in maintenance management has become very common. Good companies develop systematic processes that use the lean maintenance approach to get answers to following questions:

How much maintenance is needed?

What size maintenance crews must be used?

Can maintenance be sub-contracted?

Should maintenance staff be covered by wage incentive schemes?

Can effective use be made of computers for analyzing and scheduling activities?

Six Sigma does not create new tools but uses existing ones. The flow and sequence of these tools and statistical techniques is important.

The methodology is flexible and will not replace or diminish any technique or tool already used, but will add to them. This fear is common and must be prevented to avoid resistance that will destroy the pm program.

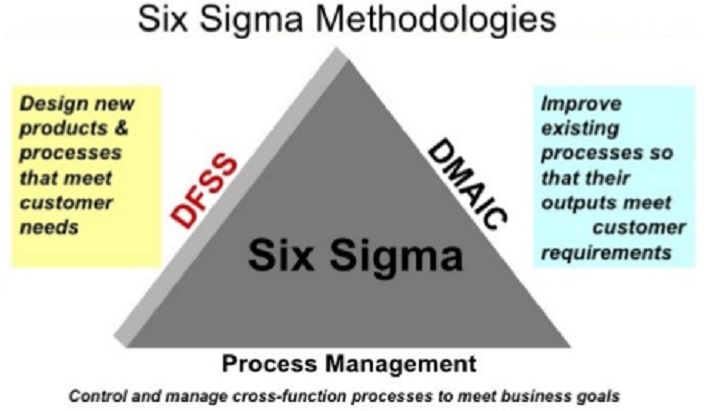

The dimensions of six sigma maintenance are:

DMAIC (Define, Measure, Analyze, Improve, Control) – Existing processes

DFSS (Design for Six Sigma) – New processes, products and services

Six Sigma Maintenance Methodologies Explained

In DMAIC methodology in maintenance, at first you have to identify work groups having good understanding of preventive maintenance techniques and possessing strong leadership commitment.

Phase D (Define)

Establish the objectives of the maintenance department and identify the critical-for-quality processes.

In this phase, leaders, planners, maintenance staff, six sigma Black Belts, and Green Belts need to work together to set departmental goals.

As there will be a large number of ideas, the first job of this team is to understand the factors in the form,

Y = f(X)

Where, X represents the input of the process,

Y the output of the process, and f the function of X

This is the most difficult stage because targets, problems, and goals may not be clear or easy to identify.

Since it is a difficult job, and the team must remember that the steps for the next phase will be drawn from this initial work.

Phase M (Measure)

After teams choose the vital few of the trivial many, the indexes, data collection plan, and analysis method can be chosen. Some common indexes include:

- Frequency of preventive maintenance

- Frequency of predictive maintenance

- Productivity

- Number of corrective occurrences

- Maintenance costs

- Downtime

- Overall Equipment Effectiveness (OEE), etc.

Phase A (Analyze)

Teams will use analysis graphs to visualize trends and to identify the root causes of the problems i.e. Pareto, scatter, run chart, box plots, etc.

Phase I (Improve)

An action plan and failure mode and effects analysis (FMEA) can help in the action definition to improve the performance of the chosen indexes.

Phase C (Control)

At this stage six sigma maintenance teams will outline a plan to retain the gains after the conclusion of the project.

The finance department will assist in investment calculations, profits, ROI, etc.

Each problem raised can be dealt with individually as a project to be led by a Black Belt and Green Belt, or a macro approach can be used—whichever is the best way to get the best performance in the maintenance department

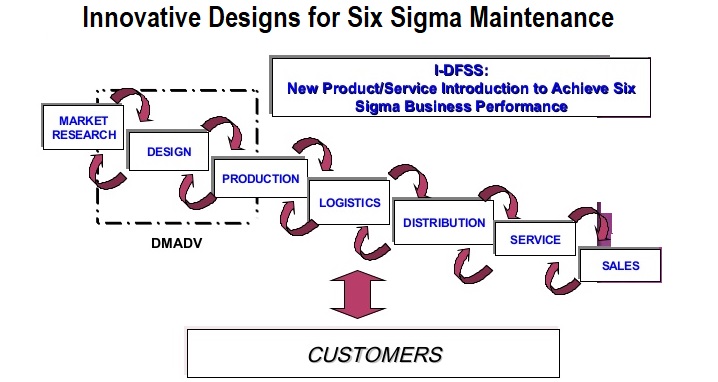

Design for Six Sigma in Maintenance

This approach targets customer-driven design of processes with 6σ capability. Additionally DFSS:

Helps in predicting design quality up front.

Top down requirements flow-down(CTQ) matched by capability flow-up.

Cross-functional integrated design involvement.

Drives quality measurement and predictability improvement in early design phases.

Utilizes process capabilities to make final design decisions.

Monitors process variances to verify 6σ customer requirements are met.

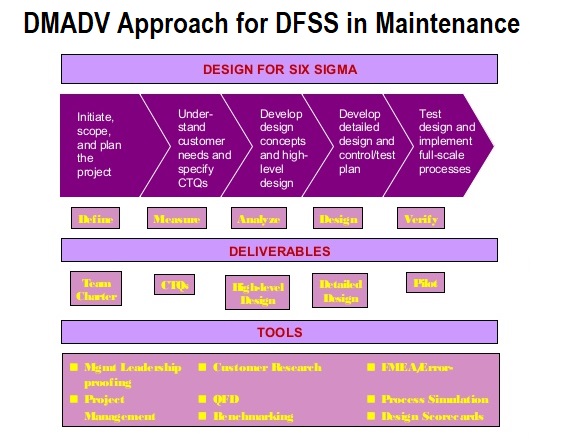

The DMADV Methodology and Tools

Enterprise asset management (EAM)

This methodology involves the management of the maintenance of physical assets of an organization throughout each asset’s lifecycle.

EAM is used to plan, optimize, execute, and track the needed maintenance activities with the associated priorities, skills, materials, tools, and information.

This covers the design, construction, commissioning, operations, maintenance and decommissioning or replacement of plant, equipment and facilities.

What is Lean Maintenance?

A systematic, logical method of identifying and eliminating waste (non-value-added activities) using continuous assessment and improvement to achieve improved maintenance effectiveness in response to customer demand

The goal of applying the lean approach is to eliminate the Non-Value Added parts of the process i.e. waste.

The goal of Six Sigma is to optimize the remaining Value Added parts by reducing variation.

The goal of TPM is perfection … generate 0 injuries, 0 defects, and 0 breakdowns

Maintenance Wastes

Motion … loading/unloading, multiple trips

Processing/WIP … unnecessary steps/approvals

Waiting … for service or parts … mechanics idle

Transportation… mechanics and parts/Employee/customer

Overproduction … overhauling vs. repairing needs

Inventory … spares (right parts, right amount)

Correction/Rework/defects… repair quality/completeness