Maintenance is activity or work that is carried out and necessary to preserve an asset including building and equipment’s. Maintenance work enables continued use and function, above a minimum acceptable level of performance, over its design service life, without unforeseen renewal or major repair activities

Maintenance management serves to protect the owners’ real estate investment in a number of ways that includes:

Physical Integrity: To keep the machines and other assets in good working order so as to minimize disruptions and downtimes.

Risk Management: To keep the assets in a state of good repair for the owners’ and tenants health and safety.

Aesthetic Preservation: To keep the assets from deteriorating in appearance and becoming unsightly.

Responsible Stewardship: To ensure that the assets achieve their full potential service life.

Duty of Care: To satisfy a legislated duty that is owed to owners, occupants and guest on the property.

Duty to Mitigate: To prevent unnecessary damage to assets that may result in their premature failure.

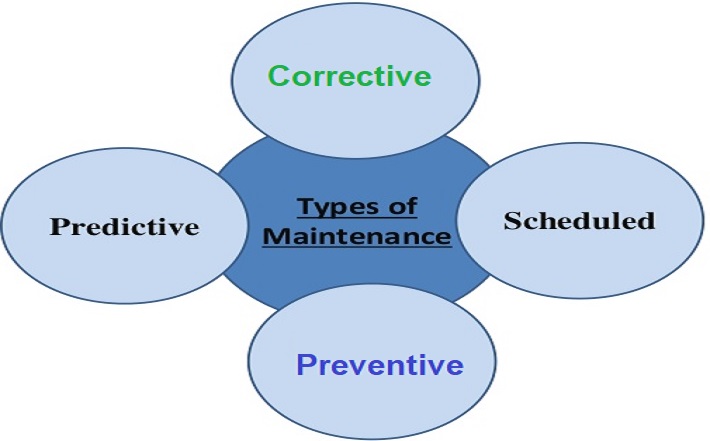

Major Types Of Maintenance

There are different types of maintenance activities.

- Breakdown maintenance

- Preventive maintenance that covers periodic maintenance, predictive maintenance and condition monitoring

- Corrective maintenance

Now lets learn more about all these types of maintenance work.

Break Down Maintenance

This is an approach in which people wait until equipment fails and then repair it. This can be one way of doing work when the equipment failure does not significantly affect the operation or production or generate any significant loss other than repair cost.

Preventive maintenance

It is a daily or routine maintenance activity that may include cleaning, inspection, oiling and re-tightening etc.

Just like human life is extended by preventive medicine, the asset or equipment service life can be prolonged by doing preventive maintenance.

Preventive maintenance helps to retain the healthy condition of equipment and prevent failure through:

- the prevention of deterioration,

- periodic inspection or

- equipment condition diagnosis,

- measure deterioration impact

This type of maintenance is further divided into periodic maintenance and predictive maintenance.

Periodic maintenance or time based maintenance consists of periodically inspecting, servicing and cleaning equipment and replacing parts to prevent sudden failure and process problems.

Predictive maintenance is a method in which the service life of important part is predicted based on inspection or diagnosis, in order to use the parts to the limit of their service life.

Compared to periodic maintenance, predictive maintenance is condition based maintenance. It manages trend values, by measuring and analyzing data about deterioration.

Condition Monitoring

Condition monitoring is the process of determining the condition of machinery while in operation.

The key to a successful condition monitoring programme includes:

1. Knowing what to listen or inspect for

2. How to interpret the collected information

3. When to use this knowledge

Successfully using this programme enables the repair of problem components prior to their failure.

Condition monitoring not only helps plant personnel reduce the possibility of catastrophic failure, but also allows them to order parts in advance, schedule manpower, and plan other repairs during the downtime.

Corrective Maintenance

This type of maintenance improves equipment and its components so that preventive maintenance can be carried out reliably. Equipment with design weakness must be redesigned to improve reliability or improving maintainability

Advantages and disadvantages of Break Down Maintenance

Advantages

- Lower start up cost

- Limited personnel requirement

- Reduced maintenance costs

- Potentially increased margins

Disadvantages

- Unpredictability

- Equipment not maximized

- Indirect costs

Preventive Maintenance Advantages

- Over all very cost effective

- Flexibility can allow for adjustment of schedule to accommodate other work

- Increased equipment life

- Saved energy cost resulting from equipment running from pick efficiency

- Reduced equipment or process failure

- Over all saving between 12% to 18%

Preventive Maintenance Disadvantages

- Catastrophic failure still a risk

- Performance of maintenance based on schedule not required

- Risk of damage when conducting unneeded maintenance

- Labour Intensive

- Saving not readily visible without a base line

Predictive Maintenance Advantages & Disadvantages

Advantages:

Increased component operational life/availability

Allows for pre-emptive corrective action

Decreased part and labor cost

Improved safety and environment

Energy savings

Over all saving between 8% to 12% over preventive maintenance

Disadvantages:

Increased investment of diagnostic equipment

Increased staff training for analyzing data

Saving not readily visible without a baseline/history

Advantages and Disadvantages of Condition Monitoring

Extend bearing service life

Maximize machine productivity

Minimize unscheduled downtime

Safely extend overhaul intervals

Improve repair time

Increased machine life Improve product quality

Reduce product cost

Enhance product safety

Disadvantages of Condition Monitoring

Monitoring equipment costs

Operational costs (running the maintenance program)

Skilled personnel needed

Strong management commitment needed.

A significant run-in time to collect machine histories and trends is usually needed.

Corrective Maintenance Advantages and Disadvantages

Advantages

Lower short-term costs

Requires less staff since less work is being done

Disadvantages

Increased long-term costs due to unplanned equipment downtime.

Possible secondary equipment or process damage.

Prone to neglect of some assets