On this page you shall learn some basic tips for HVAC Operation and Maintenance. HVAC is abbreviation for Heating, Ventilation, and Air Conditioning Systems.

Being interconnected and grouped together, this mechanical system provides thermal comfort and good air quality in an indoor space.

The components of the hvac mechanical system include Boilers, Heat Pumps, Chillers, Air Conditioners and Packaged AC System.

In this post, you shall find some really cool tips on routine HVAC maintenance.

These pieces of advice will aid you in reducing your monthly and quarterly financial outflows.

Managing a daily performance diary is one of the way to monitor and control the things.

There are many standard practices, which keeps the mechanical systems to work at a high performance during the life time of the building and the equipment.

A perfect maintenance system developer can provide the process that can help to easily maintain the comfortable thermal system.

The HVAC O&M is measured in terms of System performance.

Below is list of some hvac performance measures:

The HVAC system must offer thermal comfort continuously, at the energy use specified in the design for the building.

Continuous commissioning is the best operation that improves the energy performance by 20%.

It also improves the comfort at the equivalent time.

But, the main thing is design of the HVAC system.

The perfect design will make the system to execute properly. As the technology improves, heating and cooling performance can also improve.

Operation and Maintenance Manuals

High quality operations are ensured by good design process and regular maintenance.

All the hvac equipment manufacturer first of all have to create a manual for the operating staffs which specifies the intent clear design, maintenance list, replacement plans and all other necessary things.

The O&M manual should clearly explain the parameters that are conducted during commissioning.

Without manual, the work is never effective as it may cause many troubleshooting issues.

Maintenance Schedules

Maintenance schedule plays the important role in operation and maintenance of any equipment.

Schedules for duct filter and all other component cleaning, replacing must be specified and followed to ensure better energy use and comfort as well.

Performance of the system have to be measured monthly or quarterly, which helps the operators to collect information for the further use.

Some buildings are built up with the automation systems, which records status of the equipment’s using computer systems.

Flexibility and Occupant Behavior

It is important to cope with the requirements of the users by ensuring the safety and efficiency of the hvac system.

Arrival of heater and desk fans to the customer’s place is an indication of the failure of the HVAC system, which fails to satisfy the customer’s need.

This denotes the faults or changes in the original HVAC design and finally results in the product change for the occupant’s personal use.

Filter Cleaning & Replacement

Filters plays the important role in the Air conditioning system.

All the filters must be cleaned periodically to keep the energy and indoor air quality in a high range.

Some filters can be cleaned in simple ways like spraying water or vacuuming.

Some of them, needs replacement like filters in the ducts, filters of the furnace, heating pumps and other parts must be checked.

Filters requires regular cleaning in the HVAC system, for a long time efficient performance.

Cleaning other Components

Like filters, other components in the hvac system needs regular cleaning as well.

Ducts must be inspected regularly for the accumulation of the mold, dust and other contaminants.

For best indoor air quality, they must be cleaned and inspected for the leakage, as it may cause energy loss.

Coils with dust particles restricts the air flow which in turn reduces the convective cooling of the system.

Drains of the dehumidifying parts must be checked, as it may cause the condensed water to pool up and leaks in the building.

Operation and Maintenance of Control Systems

Programmable Thermostat schedule are important for the heating and the cooling of the HVAC System.

Those Schedules must match the occupancy and the activity of the system and must be changed in accordance to the age of the building.

Temperature, Occupancy, Humidity calculating sensors should be checked regularly for the proper operation. Improper working of sensors may be inconvenience to the users.

Improperly tuned control system are manually disable by the HVAC system, as the energy changes.

Schematic Diagrams

Diagram for duct routing and control should be created and kept for the assurance of system understanding and preventive maintenance.

It also helps in resolving and troubleshoot problems and improving the system performance by regular upgrades.

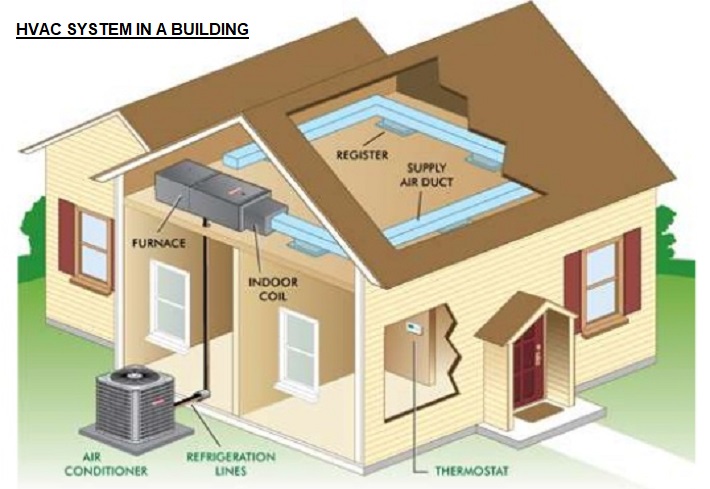

HVAC units, sensors, ducts, air handling components, controllers, and their interconnection are specified in the system.

For better readability, sensors and control diagrams are separated often.

Easy Tips on Maintenance of HVAC Systems

HVAC Systems HVAC systems, also known as central chillers, make the heaviest electricity consuming appliance in any industrial facility or building.

The contribution of the hvac equipment’s in the monthly power bill is quite significant.

For an organization or facility management department, the biggest challenge is to keep the power bills under control, for the reason that increased cost adds to the production and operation cost.

By caring for your HVAC system and keeping it in well maintained condition will help you lower your infrastructural expenditures and focus on your quality and production.

Maintain Daily Diary

Though, many would raise their eyebrow and cross-question, how would the regular recording help us descend electricity invoice?

But, by keeping a record by everyday conditions, running duration, pressure, fluid level, and other associated attributes, you can easily check, whether or not your HVAC system is working efficiently.

It also helps the maintenance experts in examining the fault in your organization’s HVAC machine.

Clean tube for smoother heat transfer

The efficiency of chillers largely depends on the silkiness of heat transfer process.

Thereby, if you want to bring down your chiller’s operation cost, you need to make certain that its tubes are clean and unclogged.

There are many pollutants that might be residing inside the tubes, affecting the performance of the machine adversely.

Condenser Performance Monitoring

Condenser supplying the chilled low- temperature water to the tube plays a pivotal part in the effective performance of the HVAC machine.

It saves the pipes from decay and improves the performance of heat transfer activity.

The low-temperature cool water also ensures the effectiveness of machine’s cooling ability.

Set the flow rate of water as suggested by technicians or as guided in the brochure of the machine.

The ideal flow rate that does not affect the performance of the application is 3 feet per second.

Having a higher flow rate more than that makes the machine overwork, which influences its performance, and adds to power bills.

Quality of Compressor Oil

The compressor is a very important unit in chillers. Special compressor oil is used for the better and efficient execution of HVAC’s performance.

The oil should be of first-rate quality.

Additionally, it should be sent for the annual quality check at your local expert of AC maintenance.

Most importantly replace the compressor oil, only, when it is suggested by the experts or manufacturer representatives.

Hope these points help some way.

Whenever you notice some disarrays in the service portrayal of your machine, it is advisable to call in skilled experts of AC maintenance.

Considering the high cost of the heating and ventilation system equipment’s and their importance for your organization, always consider contacting a professional maintenance company in your local market.