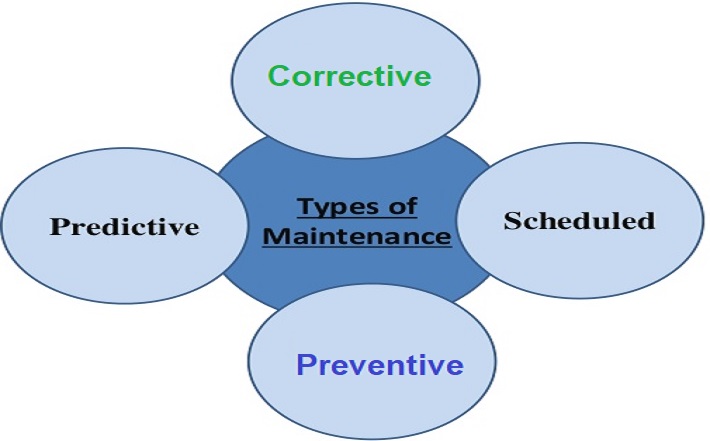

Definition Benefits and Types of Maintenance

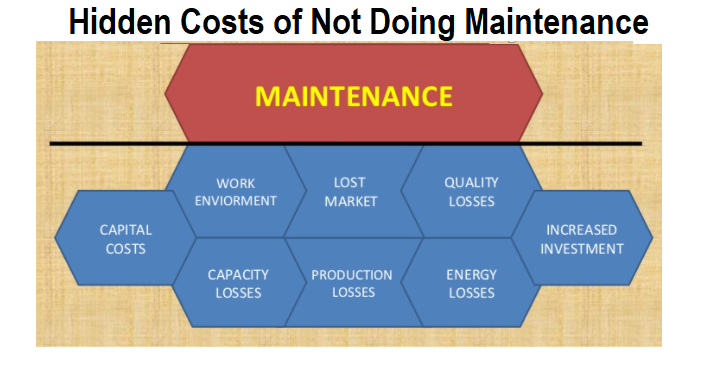

Maintenance is activity or work that is carried out and necessary to preserve an asset including building and equipment’s. Maintenance work enables continued use and function, above a minimum acceptable level of performance, over its design service life, without unforeseen renewal or major repair activities Maintenance management serves to protect the owners’ real estate investment… Read More »