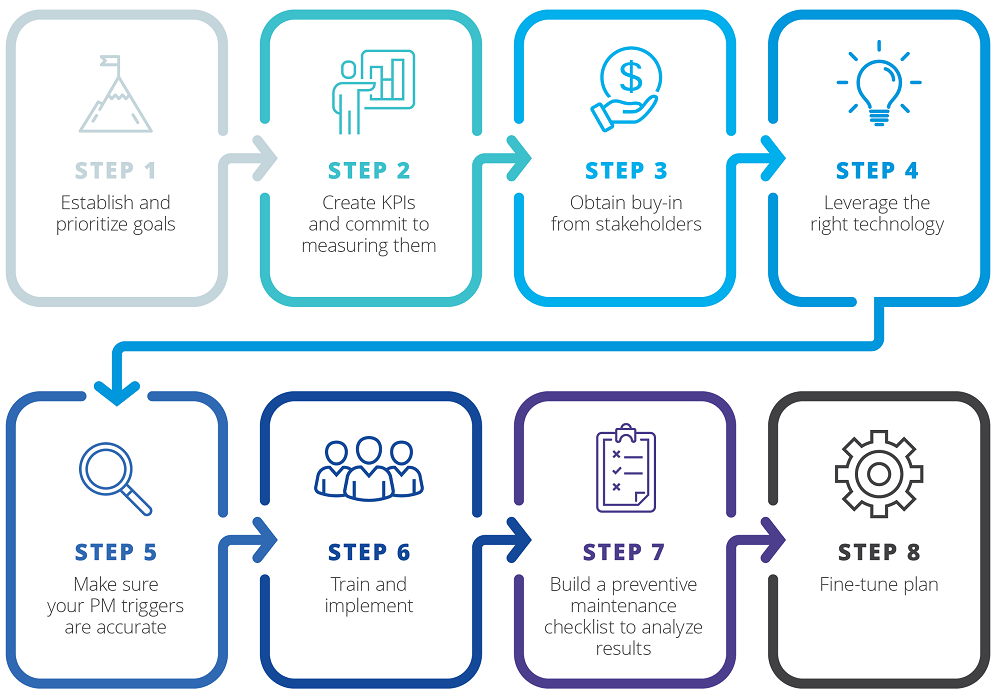

8 Steps for Successful Implementation of Maintenance Planning and Scheduling

This article about the successful maintenance planning and scheduling will help understand the proactive maintenance planning and scheduling approach. Document will also help in providing a training program for maintenance teams that is educational, exciting, and informative. The guidelines shall ensure the provision of a training environment that is conducive for training the maintenance workers.… Read More »