Purpose:

The purpose of this method statement is to establish a standard procedure for the preventive ac maintenance of split type AC Air-conditioning unit.

This method will also serve as guideline for new employees and trainees who are dealing with the maintenance of this type of air-conditioning unit.

Scope:

The scope of this standard maintenance procedure covers all split type Air-conditioning AC equipment’s which comes under the AC preventive maintenance contract and any facility management or defect liability projects.

Responsibilities

It is the responsibility of the AC technician to conduct the correct preventive maintenance on split type air conditioning units to prevent system from breakdown, thus providing the specified room temperature.

All maintenance staff shall be competent enough to conduct the activity to avoid any damage and to provide the proper result.

The maintenance supervisor and the maintenance engineer shall ensure that this maintenance procedure is available with the team to follow during the work.

Abbreviations

A/C: Air-conditioning Units

PPE: Personal Protective Equipment’s

Procedure for Split AC Maintenance and Service

Below are preventive maintenance activities which are necessary on monthly basis.

Condenser Coil Cleaning

Check the condition of the condenser coil. If it seems still clean, extend the frequency of cleaning to next month. If you find that its condition is not satisfactory, then perform the following procedure step wise:

Before starting the ac maintenance work, wear safety shoes, gloves and goggles.

Ensure the availability of following tools:

- Screw driver

- Jet pump

- Chemical cleaning agent (if applicable)

- Multimeter

- Adjustable wrench.

Turn off the air conditioning split unit.

Isolate / switch off the Isolator switch.

Set-up the pressure washer pump by tapping it to a water supply and connecting it to the correct power source.

Dilute the chemical cleaning agent to a container of water.

Apply the diluted solution to the condenser by pouring it along the fins.

Wait for 10 minutes so that the chemical can be absorbed inside the coil.

Rinse the coil with water and slowly work the spray up and down the fins.

Direct the spray nozzle so that it is parallel to the fins. Do not spray at an angle to the fins because they could be bent and may cause damage to the coil.

Let the water drip and dry all components before starting the unit.

Start up the split ac unit if no other split unit maintenance is necessary.

Cleaning of Air Filters

- Prior to the work, wear safety shoes, gloves and goggles.

- Prepare screw driver.

- Switch off the a/c unit.

- Remove or lift the cover of the indoor a/c unit.

- Remove the air filter.

- Clean using jet pump or running water.

- Let the filter dry.

- Install the air filter.

- Put back the indoor a/c cover.

- Start the unit.

Annual Preventive Maintenance of Split AC Unit

Prior to the work, wear safety shoes, gloves and goggles. Prepare tools like multi-meter, jet pump, chemical cleaning agent, gauge manifold and refrigerant cylinder.

Compressor Checking:

- Check for any undue noise or vibration.

- Check anti-vibration mounting; replace if found defective.

- Check compressor motor current using clamp ammeter.

- Clean and paint compressor body.

Condenser Fan Motor Checking:

- Clean condenser coil with pressurized water and with approved chemical.

- Dismantle condenser fan blade. Check for defects, replace if found any. Clean and paint fan blade.

- Check fan motor. Conduct insulation resistance on the motor.

Controls and Safety Devices Checking:

- Check operation of H.P. and L.P. cut-out switch. Replace if found defective.

- Check operation of thermostat.

Control Panel and Isolator Switch

- Check and clean all magnetic contactors.

- Repair or replace if found any defects.

- Check delay timer where applicable.

- Start the unit and check the running capacitor.

CHECKING OF AC CAPACITOR

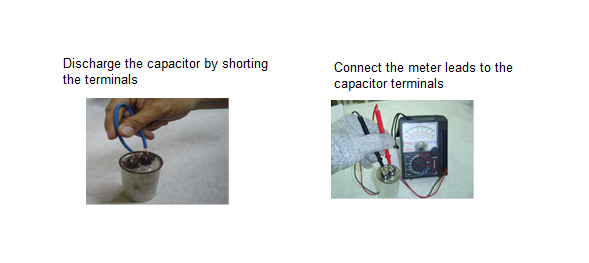

Disconnect capacitor from the unit.

Discharge the capacitor by shorting the terminals using a piece of wire.

Capacitors must be discharged before testing to prevent damage to the meter.

Connect the meter leads to the capacitor terminals.

Meter should be in resistance mode.

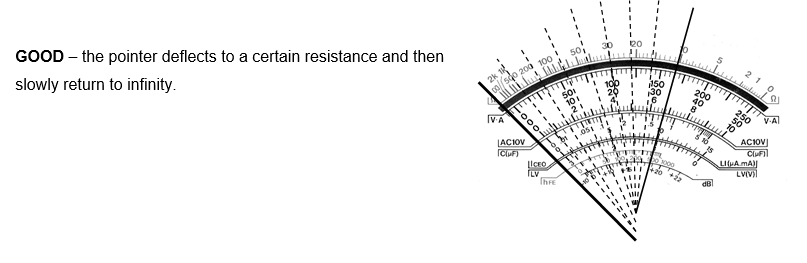

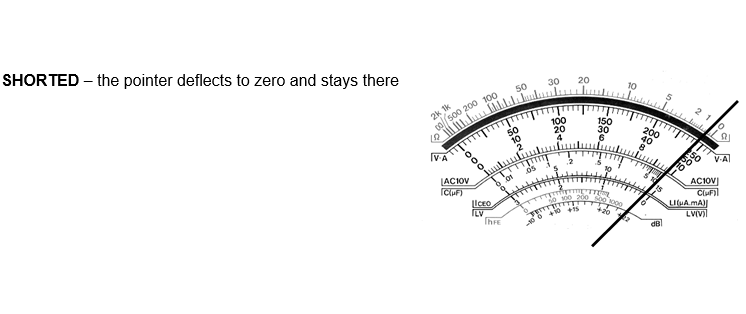

Observe the deflection of the meter pointer.

GOOD – the pointer deflects to a certain resistance and then slowly return to infinity.

SHORTED – the pointer deflects to zero and stays there

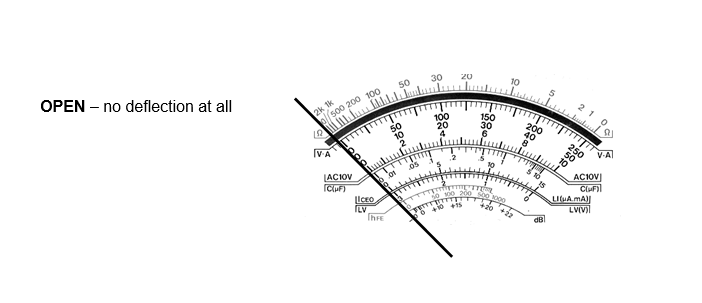

OPEN – no deflection at all

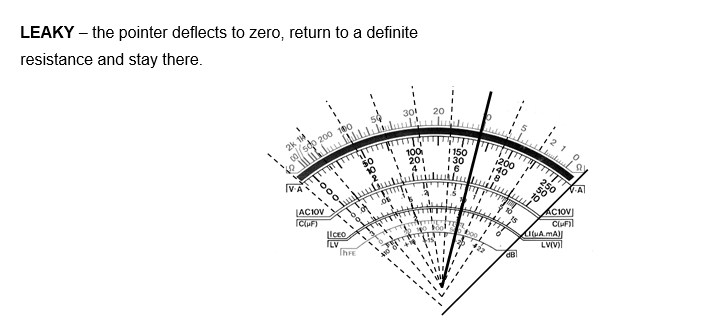

LEAKY – the pointer deflects to zero, return to a definite resistance and stay there.

If the capacitor is defective, mark it using a permanent marker or a piece of masking tape.

- Check for loose terminal connection.

- Tighten if found any.

- Clean control panel.

- Check operation of isolators.

Evaporator Fan and Motor

- Check for any undue noise and vibration.

- Check the condition of the blower. Inspect for any defects; repair or replace if found any.

- Check the motor condition, inspect for bearing defects. Get actual motor current using clamp ammeter.

Evaporator Coil and Drain System

- Clean cooling coil with jet pump.

- Clean the air filter. Replace if already damage.

- Condensate drain line to be de-clogged using pressurized air.

- Clean drain tray for sludge and dirt.

General AC Maintenance Points

- Check refrigerant pipe insulation condition. Damage portion to be change.

- Check for damage and missing brackets and supports.

- Replace if found any damage.

- Paint rusted portion of supports and brackets.

- Refrigerant pipe to be wrapped with canvas cloth and to be covered with two coats of weather proof paint.

- Scrape and paint the rusted portion of the outdoor unit.

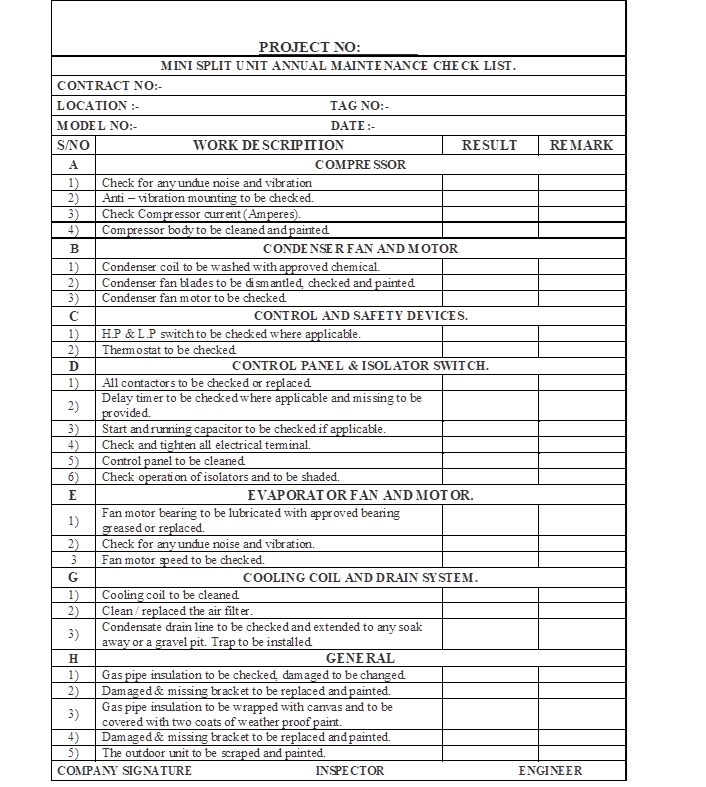

Attachment – Annual AC Maintenance Checklist for Split AC Unit